Even though it is great to see this technique in action, I tend to wonder at the efficiency of what happens in this ![]() : instead of just making a new handle for the brush axe that needs one, the handyman here wants an aluminum handle, and makes it from soda cans!

: instead of just making a new handle for the brush axe that needs one, the handyman here wants an aluminum handle, and makes it from soda cans!

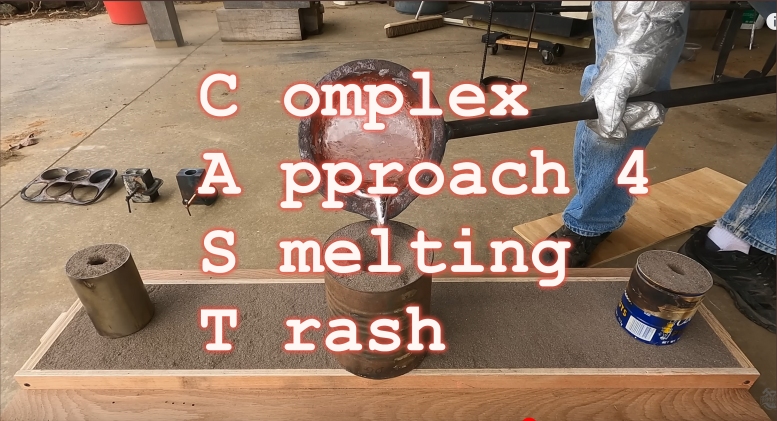

So imagine the process, first making a handle from two pieces of wood, which already requires the use if heavy woodworking machines, then splitting it in half again. Next melting over 600 cans (imagine having to drink all that), which uses a lot of gas. Then making a two part mould and again melting the aluminum. Casting the handle, then finishing it of, which requires metalworking tools.

Efficiency wise it may not be worth the work for the longer lifetime of the handle, but it is a nice way to recycle the cans. Here in the Netherlands politics has put a 15 cent return on cans, but that just makes it so people either don't care about it anyway, or people with lower incomes start to spend their free time collecting cans for cash.